SUCCESS STORY

Erlenbach convinces in EPP test series

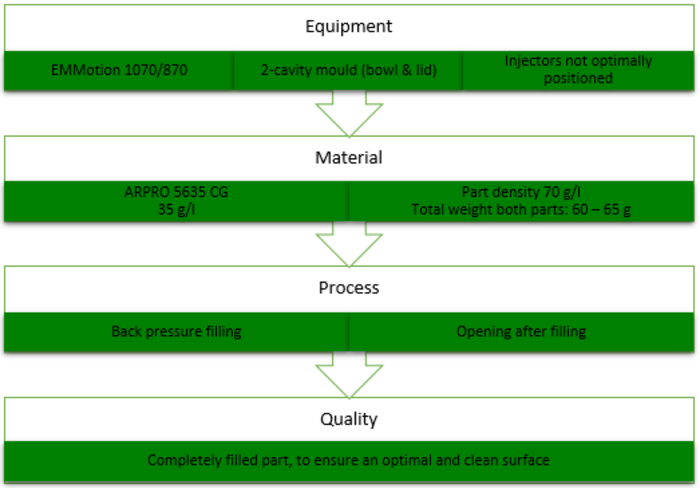

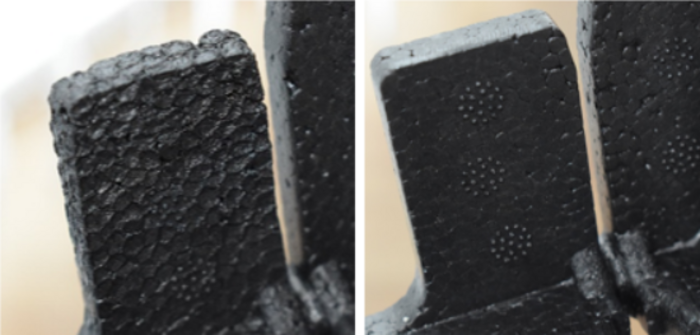

A well-known European EPP processor came to us at the Experience Center with very precise ideas regarding the quality of its end product, as well as a number of dos and don'ts within the process steps. The requirements were exciting, but could be solved with the Erlenbach equipment.