Moulding machine / EMDynamic

POWERFUL AT ALL LEVELS

The EMDynamic achieves goals in a unique way, which for a long time could only be realized by hydraulically driven systems. With the EMDynamic, #teamerlenbach presents a solution that not only meets long overdue economic requirements with its purely electric drive and purely electric locking, but also clearly convinces with many other advantages in the production process.

Typical applications

- optimized for large, deep and complex molded parts

- common applications are found in the automotive & HVAC field

Which materials can be processed?

-

all common particle foams

-

processing pressure: max 5 bar

EMDynamic // Sizes at a glance

| wide | hight | max. size of shape mold | |||

| S / | 1345* | 1145* | 1345x1145 | ||

| M / | 1650* | 1380* | 1650x1380 | ||

| L / | 2100* | 1450* | 2100x1450 |

*maximum clamping surface: +350mm

Options

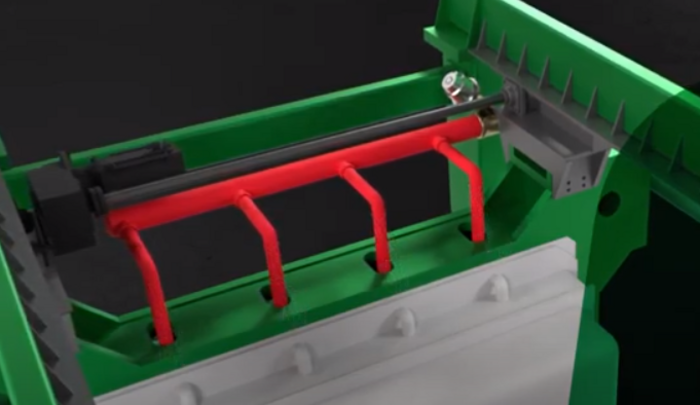

- EMDynamic filling package

- Multizone cooling

- Separate cooling water circuits

- Electric chain hoist

- Core pull / dividing-plate / multi densiy application

- EMHandling up- and downstream automation

- 2-axis portal

- Robots

- Material mixing by EMRemix

- Service contract

To our product video

Watch the product video of the Erlenbach EMDynamic shape moulding machine.