Shape moulding machines 5.0 / 2.5 for EPP, E-TPU & Copolymer

A REAL ALL-ROUNDER

The EMMotion variants are without a doubt, two of the flagships within the Erlenbach fleet. And for good reason: they are quiet, energy saving, precise, especially flexible in their handling and a match for almost any task.

And most important of all: they run, and run … and run. Especially because the electric moulding machine achieves maximum performance while needing very little maintenance. A real Erlenbach machine.

Typical applications

- Your first choice for applications with crack filling

- positioning accuracy 0,1 mm

- Production of small to large batch sizes

- Especially suitable for food packaging

Applications

- Packaging

- Automotive (bumpers, sun visors, etc.)

- moulding parts for home technology

- other technical moulding parts e.g. for building technology

Which materials can be processed?

- Material processing: max. 5 bar or 2,5 bar

- EPP, E-TPU, EPS, copolymere and biopolymere

EMMotion 5.0 / 2.5 at a glance

- Dynamic electrical servo drive

- Solid machine frame made of torsion resistant steel profiles

- Hot galvanised and high quality coating

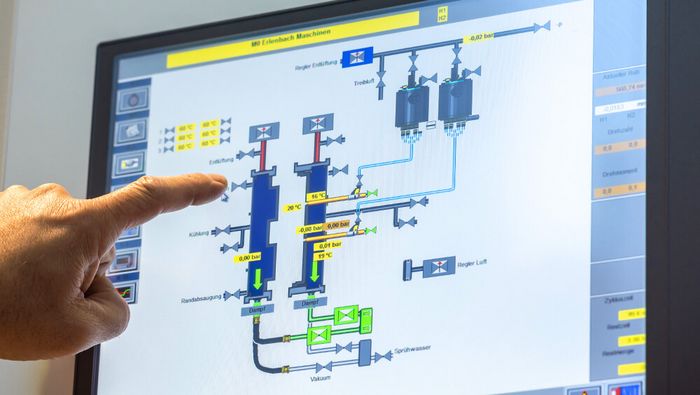

- Fully electronic regulation systems

- EM quick mould change system with machine platform and clamp frame

- Insulated EM steam chamber systems

- Individual machine stroke variants

- Situation analysis via teleservice

- User-friendly HMI

- Process data logging

Options

- Foam pressure sensor

- Multizone cooling

- Separate cooling water circuits

- Female chest extension

- Electric chain hoist

- Core pull / dividing plate / multi densiy application

- Central or single vacuum unit

- Eletric ejector plate

- Additional clamp frame

- EMHandling up- and downstream automation

- Material mixing by EMRemix

- Service contract