COPOLYMERE

THE PERFECT MATCH

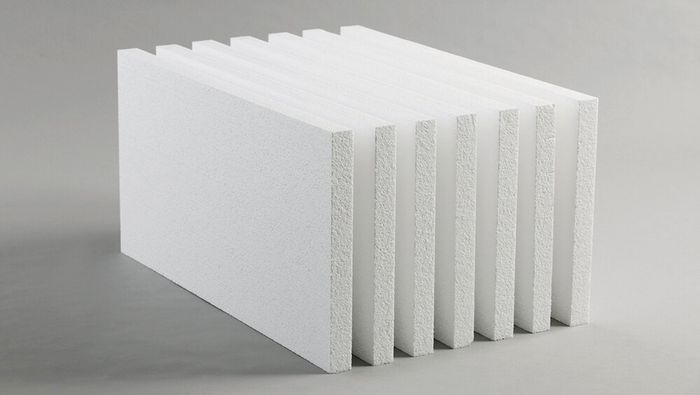

Perfect combination for even more versatile results: Modern copolymers can combine the known advantages of EPS and EPP, thus offering you many additional and novel application options.

For example, polylactide (PLA) is a bioplastic whose biogenic raw materials have been chemically modified.

Depending on the raw material, certain copolymers can easily be processed on our EMMotion 1.6 or EMMotion 2.5 moulding machines and can even be pre-expanded on our EMBead.

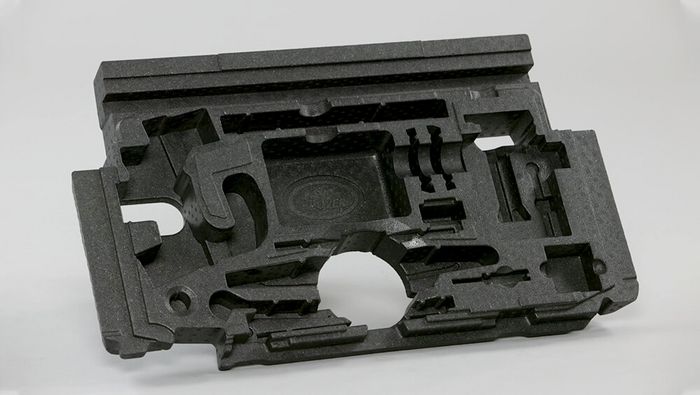

Packaging is one area where there are some familiar uses for copolymers. Copolymer processing for the automotive sector is another recent trend.

Whichever copolymer is the right one for your applications, with the machines from Erlenbach, you can be sure of having the right equipment both now and for the future.